- Home

- |

- CSC Combined Data Plate

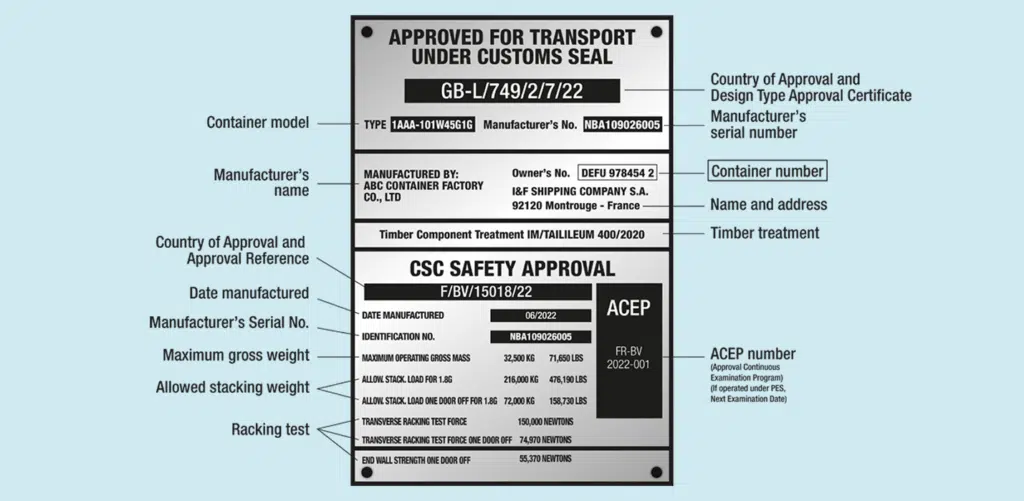

CSC Combined Data Plate

The Safety Approval Plate, conforming to the model reproduced below, shall take the form of a permanent, non-corrosive, fireproof rectangular plate measuring not less than 200 mm x 100 mm.

The words CSC SAFETY APPROVAL, of a minimum letter height of 8 mm, and all other words and numbers of a minimum height of 5 mm shall be stamped into, embossed on or indicated on the surface of the plate in any other permanent and legible way.

All characters shall be of proportionate width and thickness, they shall be durable and in a colour contrasting with that of the container.

CSC – THE CONTAINER SAFETY CONVENTION

In 1972, a Convention for container safety was adopted at a conference jointly convened by the United Nations and the International Maritime Organisation. This was the International Convention for Safe Containers (CSC) and it has two important goals:

- To maintain a high level of safety of human life in the transport and handling of containers.

- To facilitate the international transport of containers by providing uniform international safety regulations.

Countries that have adopted the CSC convention are known as Contracting Parties and their Governments are known as Administrations.

Administrations normally entrust testing, inspection and approval to authorized organizations, such as Classification Societies.

Approvals are accepted by all other Contracting Parties, which means that, once approved, containers are able to move in international transport with the minimum of safety control formalities.

WHAT IS THE CSC PLATE?

The convention requires that any container used for international transport must be fitted with a valid safety approval plate (CSC Plate).

The CSC plate is fastened to every shipping container at the time of manufacture and is typically riveted to the outside of the left door.

Each CSC plate must contain a certain level of information, in either English or French. The words “CSC SAFETY APPROVAL” are prominent on the plate, along with the country of approval and the approval reference.

The date of container manufacture, specifically the month and year, must be evident. As must the manufacturer’s container identification number or, in the case of an existing container without a manufacturer number, the Container Operator’s operational number (using a “BIC Code”) or the number allotted by the Administration. The container’s maximum weight-carrying capability (usually referred to as “Payload” or “max net mass”) in both kilograms and lbs must be inscribed, along with the stacking and racking test load value.

NOTE: The CSC Plate is today typically included as part of a Combined Data Plate, which includes the other plates necessary for containers to be used in international trade, namely:

- The Customs plate (referring to the Customs Convention for Containers (CCC) requirements) showing the certificate applicable to the container to allow transport under customs seal.

- The timber treatment applied to the wood flooring of the container as required by the Australian agriculture authorities

- Optionally, the Owner’s plate carrying the name of the container’s Operator and its operational number (using the “BIC Code”)

CSC Inspections

Container owners are responsible for maintaining containers in a safe condition and must ensure containers are inspected at intervals appropriate to operating conditions. However practical considerations, commercial practice, and contractual agreements mean that this responsibility is transferred to the party in control of the container.

For maximum inspection intervals see below. Two inspection programs are offered in the CSC:

- Periodic Examination Scheme (PES):

Every container must be examined not more than 5 years after manufacture, and thereafter at intervals of less than thirty months. The date of the next inspection (NED) is required to be marked on the CSC plate - Approved Continuous Examination Programme (ACEP).

Deems the container to have been properly examined every time a repair is carried out or, in many cases, every time a container is inspected at a repair facility. Containers operated under an ACEP scheme must display the scheme number on the CSC plate, this is often in the form of a decal.

Contracting parties are required by the Convention to make the list of the ACEP schemes approved under their authority publicly available.

The IMO’s recommended method of publication is the Global ACEP Database operated by the BIC.

CSC VALIDITY AND CONTAINER INSPECTIONS

Irrespective of the inspection system followed, the CSC plate is only valid if the container is in good order. If it is damaged during service and is no longer safe to use, the owner must act accordingly. Any authorised agent can take the container out of service if it is deemed to be damaged to a dangerous level. Annex 2 of the CSC includes a set of criteria to help agents determine whether transport restrictions must be applied, including immediate removal from service.

WHERE TO LEARN MORE

Container owners and operators are encouraged to study and keep the latest version of the CSC on-hand. To order a copy, visit the website of one of the distributors listed on the IMO’s website: http://www.imo.org/en/Publications